FTF Group® is a world-renowned specialist designer and manufacturer of space conditioning products for indoor climate/environments. FTF Group® has extensive experience dating back over 80 years and are at the forefront for the design, development, and manufacture of water driven cooling and heating technologies.

UK Office & Factory

Manufacturing of their products take place in-house at their UK Head Office and Technical facility in Derby, with the state-of-the-art facility allowing for the manufacturing capability required to deliver the most complex of bespoke solutions.

Included in their facilities are the latest bespoke manufacturing machinery as well as a dedicated powder-coat paint plant to paint all of the components of their Multi-Service Chilled Beams.

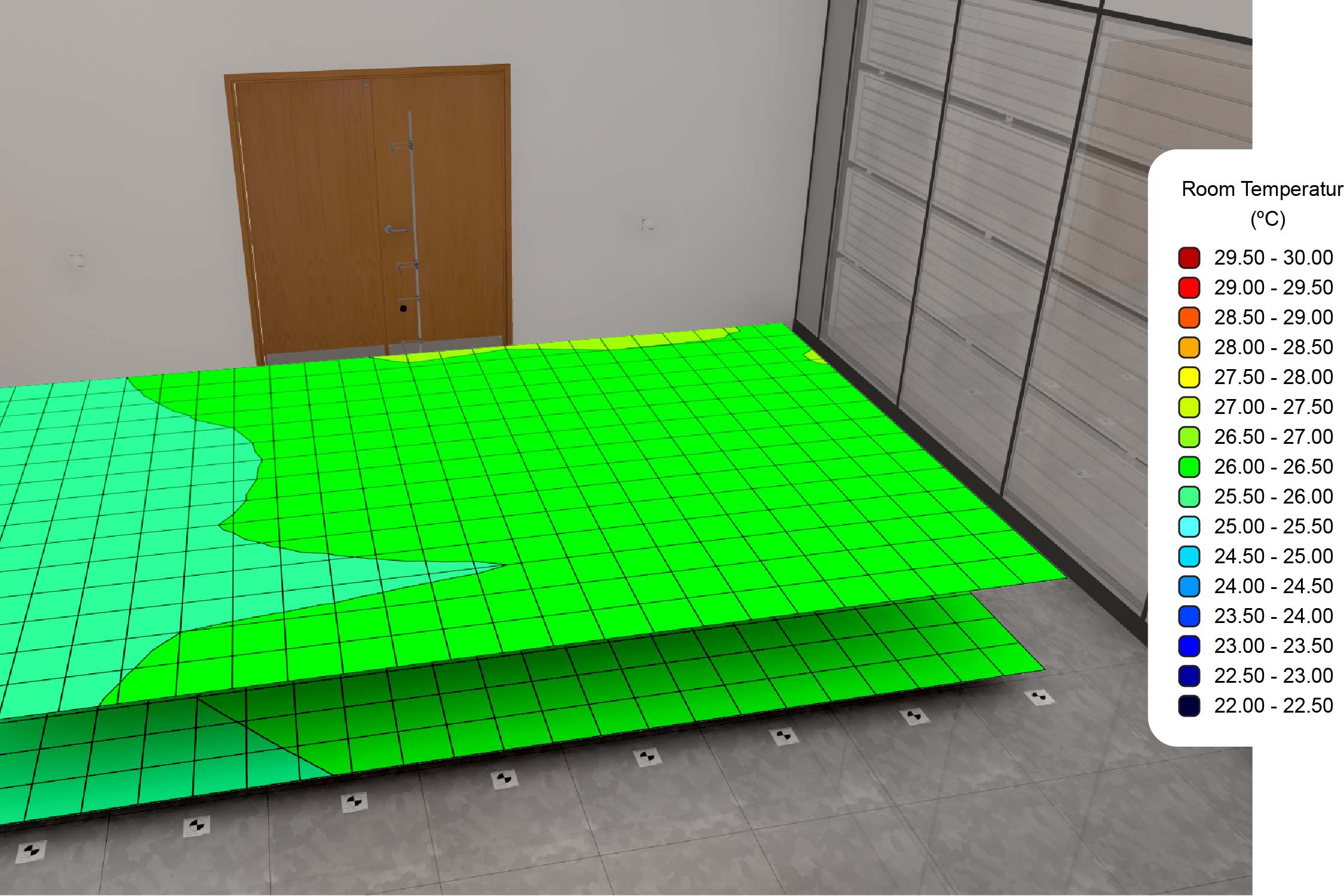

At their UK head office, FTF have significantly invested in their in-house testing facilties. FTF Group® have 3x Climatic Test Laboratories, 2x Photometric Test Laboratories, and 1x Acoustic Test Laboratories to allow for project-specific in-house mock-up testing, allowing the client to fully asses the proposed system and determine the resulting Indoor Air Quality (IAQ) and Thermal Comfort conditions.

Testing Laboratories

Each in-house Climatic Laboratory has internal dimensions of 6.3 x 5.7 x 3.2m and includes a thermal wall so that both core and perimeter zones can be modelled.

FTF Group® employ the use of state-of-the-art thermography technology with FLIR® thermal imaging cameras, which help to determine the most efficient way to improve project specific installations, as well as further the development of their spatial conditioning technology.

The two in-house Photometric Laboratories are used to evaluate the performance of luminaires. To measure the performance, it is necessary to obtain values of light intensity distribution from the luminaire itself.

Luminaire outputs are measured using their integrating sphere for smaller luminaires or their large integrator room for large fittings and Multi-Service Chilled Beams. For other methods, FTF can use traceable calibrated radiant flux standards for absolute comparisons.

The in-house Acoustic Test Laboratory is a hemi-anechoic chamber which utilises sound absorbing acoustic foam material in the shape of wedges to provide an echo free zone for acoustic measurement.

The height of these acoustic foam wedges has a direct relationship with the maximum absorption frequency, therefore they had the wedges specifically designed to optimise the sound absorption at the peak frequency normally found with their Active Chilled Beam products.

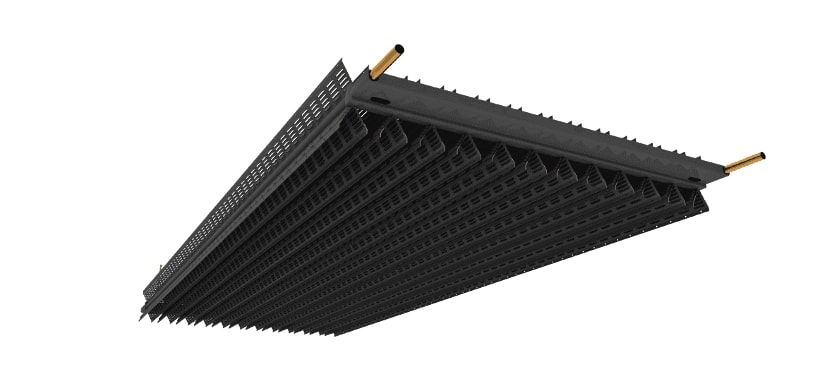

Products

FTF Group® employs professional project managers, designers, mechanical and electrical engineers; the company has a reputation for delivering complex projects on time, within budget and to specification.

To meet architectural expectations, FTF Group® employs in-house 3D computer generated modelling using various different software design packages which include Solidworks, Revit and can even produce building fly throughs.

Frenger's Product Range includes:

Their Technical Facility and Head Office is predominantly based on the prestigious Pride Park, Derby in the United Kingdom, with global offices in Australia and America.

FTF Group® has earned an enviable reputation as a dependable supply partner capable of developing effective space conditioning solutions for the most complex of projects. BIM models of most of their products are available.

To find out more about Frenger® and their highly efficient HVAC product solutions, click the button below to view their company videos page. There you can find various videos ranging from project showcases, in-house state-of-the-art testing laboratories, CPD webinar adverts, and HVAC exporting.

View below a selection of their company brochures to learn more about how FTF Group's HVAC product solutions and expertise can add value to your project..