183 Clarence Street (Substation 164) Where Heritage Meets Innovation

FTF Group® have supplied 183-185 Clarence Street, Sydney ( SubStation No. 164) to provide one of the most distinctive commercial office spaces in Sydney CBD which utilises both FTF Group's® Compact™ Active chilled beams and X-Wing® Radiant passive chilled beams on the same project to bring two Historic Buildings back to life.

After sitting empty for two decades, two historic buildings in Sydney have been given a new life to bring together one of Sydney’s most innovative office towers and setting the benchmark for heritage buildings for the future.

A striking seven-level abstract glass extension sits atop the restored building so that it seems to float above the streetscape. The triple-glazed Curvilinear glass design flips the modern workplace on its head – resulting in a unique, open and innovative office workspace.

FTF Group® were selected to supply both their slimline Compact™ Active chilled beams and X-Wing® Radiant Passive chilled beams to deliver an energy-efficient solution which compliments both the new building addition as well as the pre-existing heritage buildings to respect the buildings heritage and character.

Bringing two historic buildings back to life is a more sustainable and Low Carbon approach as opposed to demolition and rebuilding, which isn’t an option for so many beautiful heritage buildings that, while energy inefficient, are so important to the history of our cities. The use of FTF Group's® chilled beam technology can make the building energy efficient.

183-185 Clarence Street, Sydney ( SubStation No. 164) is targeting a 5 Star Green Star Rating and 5 Star NABERS Energy Base Building Rating which rewards the environmental and healthy design features implemented in the project. The developer (Built) is to use 183-185 Clarence Street as its new headquarters it is targeted as a 6 Star Green Star energy efficiency rating and a Platinum WELL rating for its office fitout.

A WELL rating is a more human-centric rating system that prioritizes building decisions which support the health and wellbeing of its occupants. It’s a rating often only considered for new buildings but the developer (Built) is excited to show how the very highest level of WELL can be attained even in an existing heritage building.

The reuse of the heritage buildings and much of the internal building fabric, including elements of both exceptional and high heritage significance, is valuable not only for preserving their heritage but contributes to a significant reduction in the carbon footprint of the redevelopment.

From a life-cycle assessment study undertaken by the developer (Built), it calculated the value of retaining the heritage façade, floors and column structure to be a 24% reduction in embodied carbon compared to conventional construction.

The developer (Built), even relocated their headquarters to the building to showcase their capabilities as an innovative builder. The building, located inside the heart of Sydney's CBD and is valued at over $200 million, was formerly an electrical warehouse and prior to that in 1909 was a sprits warehouse.

Last-minute Covid safe measures were installed to help safeguard building occupants throughout the pandemic including:

- Contactless automatic doors

- Sanitary fixtures to bathrooms

- Access control lifts

- Space within office lobbies to fit temperature checking machines/devices

A key focus of the development, end-of-trip facilities were installed, to help maximise occupancy wellbeing and health, as well as providing an alternative to public transport. These facilities provides high-quality housing for up to 66 tenant and 33 visitor bikes.

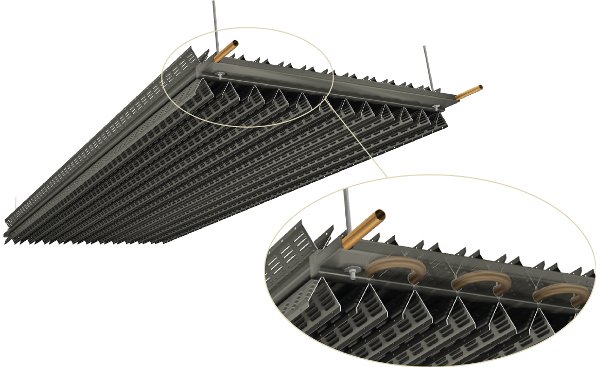

X-Wing® Radiant Passive Chilled Beam

FTF Group's® 'Exposed' X-Wing® Radiant Passive Chilled Beams (40% Radiant quotient) were also supplied to provide both cooling as well as deliver excellent indoor climate environment which is essential for employee wellbeing and performance. Our X-Wing® is constructed from copper and aluminium and is 100 percent recyclable. The copper coil is produced by FTF Group's® in house fully automated bespoke "state of the art" full CNC serpentine bending machine. This produces seamless sinusoidal copper coils (without any joints in the product, hence no risk of water leakage), with up to 12 water passes at 70mm tube centres. The aluminium radiant "wings" are produced in house by bespoke power press and roll forming machines, all of which are then assembled by FTF Group's® fully automated CNC controlled machine which mechanically bonds the "radiant wings" to be in metal to metal contact with the seamless copper waterways.

The use of Radiant Passive Beams enables additional cooling for peak loads by use of thermal mass storage as FTF Group's® X-Wing® Radiant Passive Beams cool the exposed concrete slab of the building by direct radiant exchange and this enables fewer X-Wing® units to achieve and maintain the design summer room condition for cooling.

Compact® Active Chilled Beam

FTF Group's® slimline Compact™ Active Chilled Beam were supplied to provide the cooling, heating and ventilation whilst providing a low noise solution that delivers good thermal comfort levels. All our Compact® Active Chilled Beams were supplied with Air Management Discharge Vanes 'AMDV' concealed within the beam and smooth curved discharge slots for enhanced aesthetics and superior air distribution as we provide full Coanda effect and 'fan shape' distribution. The Coanda effect is initiated within our Compact® Active chilled beam to ensure horizontal discharge for optimal thermal comfort levels.

You can learn more about the Active and Passive Chilled Beams FTF Group® has to offer by visiting our products page. Alternatively, you can contact our office on 646-571-2151 or sales@ftfgroup.us.