Testing Testing 1,2,3

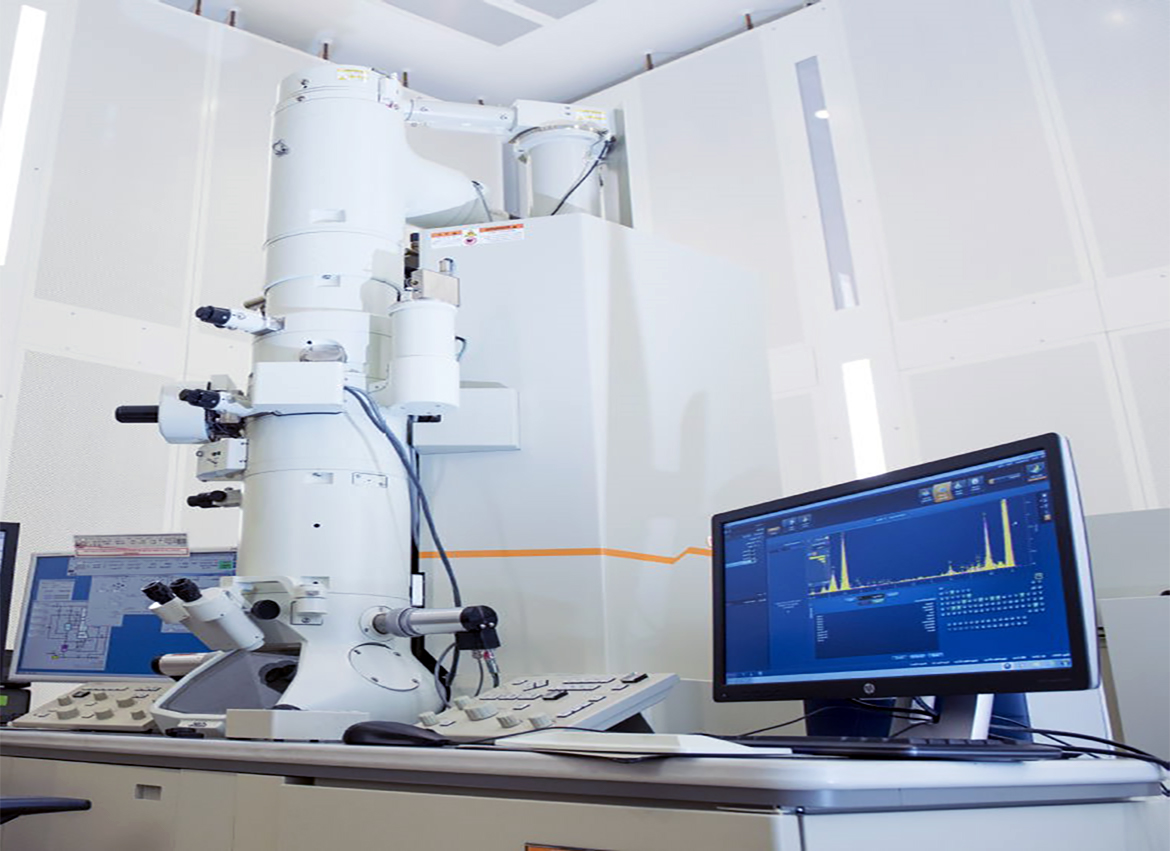

FTF Group have successfully designed, tested, manufactured and supplied their bespoke energy-efficient cooling solutions to various state-of-the-art Scientific Testing and Electron Microscope Laboratories across the globe.

Many world-class research facilities contain state-of-the-art testing equipment that require the room environment / performance conditions to be precisely controlled for equipment operation. This can present many challenges such as:

- Close temperature and humidity control

- Low air velocity movement

- Low noise

- Low vibration

- Minimal maintenance

- Non-Magnetic Construction

Considering the above challenges, over the years FTF Group have successfully developed several cooling and heating solutions for these types of facilities. Our water-driven solutions, which operate using elevated chilled water supply, provide sensible 'Radiant Cooling' to remove the heat from the laboratory using radiant absorption which helps to minimize air movement within the space and maintain close temperature control of the room condition. This is critical given that modern research facilities contain state-of-the-art testing equipment which is sensitivity to air velocities, noise and temperature.

FTF Group offer full design support to ensure our products are carefully coordinated with the testing equipment within the facility.

Solution 1 – Exposed X-Wing® 'Radiant' Passive chilled beams

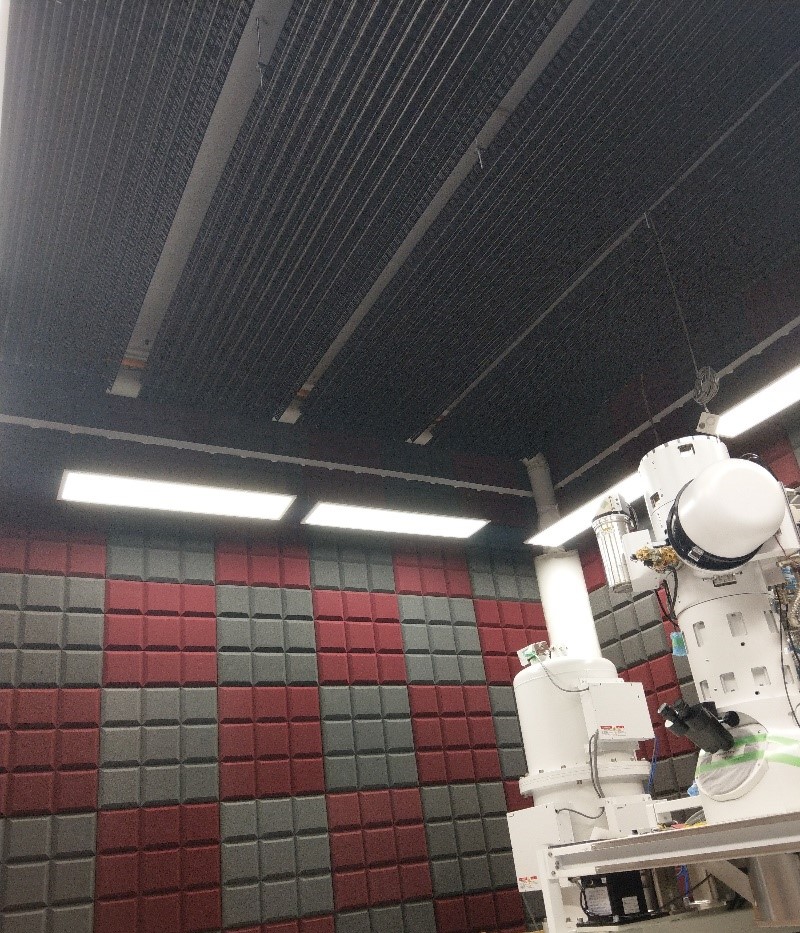

FTF Group's range of 'Radiant' Passive chilled beams are designed for high-level installation (i.e. mounted below the soffit) to deliver higher cooling outputs within the laboratory. Our X-Wing® 'Radiant' Passive chilled beams have a 40% radiant cooling quotient to provide an efficient means of cooling the room whilst maintaining very low air movement and low noise operation within the space. As our X-Wing® product is mounted at high level this offers the opportunity to utilize the walls of the room for acoustic absorption whilst having a separate displacement ventilation system to provide dehumidification.

Our X-Wing® product is constructed from copper and aluminum and is 100 percent recyclable. The copper coil is produced by FTF Group's in house fully automated bespoke "state of the art" full CNC serpentine bending machine. This produces seamless sinusoidal copper coils (without any joints in the product, hence no risk of water leakage) up to 18' 8" in length, with up to 12 water passes at 23⁄4" tube centers. The aluminum radiant "wings" are produced in house by bespoke power press and roll forming machines, all of which are then assembled by FTF Group's fully automated CNC controlled machine which mechanically bonds the "radiant wings" to be in metal to metal contact with the seamless copper waterways.

Exposed X-Wing 'Radiant' Passive beams at University of Wollongong, NSW Sydney

Solution 2 - X-Wing 'Radiant' PCB's

FTF Group also offer 'Radiant' PCB's which are designed for high level installation (i.e. mounted within a perforated casing directly below the soffit) to deliver higher cooling outputs within the laboratory. Our X-Wing® 'Radiant' PCB's deliver 40% radiant cooling quotient to provide an efficient means of cooling the room whilst maintaining very low air movement and low noise operation. Our X-Wing 'Radiant' PCB's can be supplied to accommodate our services such as integrated LED lighting and presence detection sensors (if required) to provide a single plug and play prefabricated solution.

Again, this solution is normally used in conjunction with a separate displacement ventilation system to provide dehumidification.

X-Wing 'Radiant' Passive PCB’s at Oxford University – Beecroft Building

Solution 3 - Wall Mounted Radiant Cooling / Heating Panels

FTF Group's range of Wall Mounted Radiant Panels are designed and selected to handle the sensible cooling and/or heating requirements within the laboratory. This is achieved by radiant exchange between the wall-mounted panels and the components within the room (i.e. radiant exchange does not rely on air movement to provide the cooling/heating), whilst a separate displacement ventilation system is normally deployed for dehumidification.

FTF Group's range of Wall Mounted Radiant Panels (can be supplied perforated or smooth-faced panels) are constructed from copper and aluminum and are 100 percent recyclable. FTF Group also manufacture Integrated LED Lighting for use in their Laboratories Cooling and/or Heating Solutions. The FTF Group luminaire has been purpose-developed using Good EMC Engineering practices and incorporates EM Mitigation measures within its design to ensure compliance and to enable its use within microscope rooms.

Vertical Wall Mounted Water Driven Cooling Panels at Warwick Universities Electron Microscopy Research Facility

For more information on FTF Group's cooling solutions or if you require design support selecting our products then please email: sales@ftfgroup.us.