What Products are most suited for Cooling Hospitals?

Chilled Beams are a tried and tested technology predominantly used in 'owner occupied' buildings or buildings where the person paying the energy and/or maintenance bills are influential in the HVAC equipment selection / solution. One such sector is 'Healthcare'.

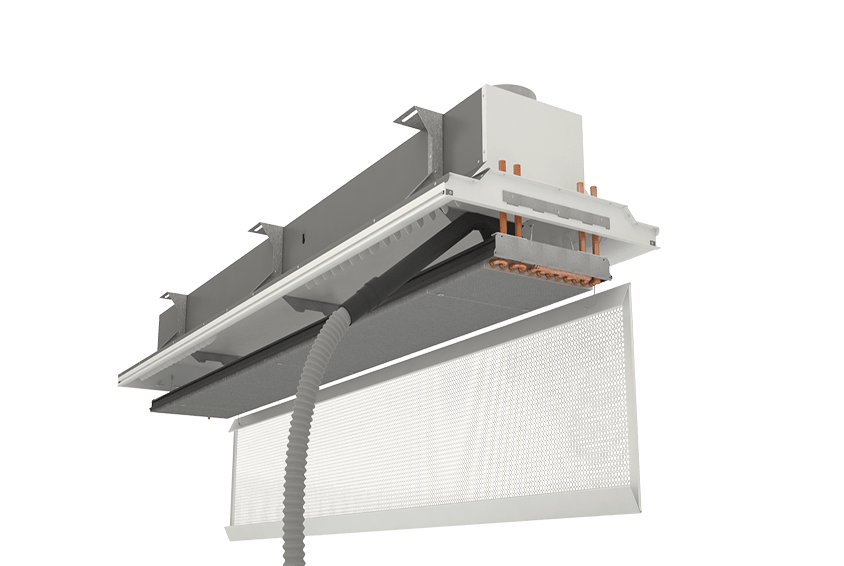

FTF Group® mainly ultilise their Eco™ and Halo Active Chilled Beams with easy clean upgrades for Healthcare applications. FTF Group's Eco Healthcare and Halo Healthcare active chilled beam units provide easy access to the 'dry' heat exchanger coil as the drop down battery feature is standard on all FTF Group® 'Healthcare' beam units. Given that there are no moving parts and a dry coil (operates above dew point) maintenance is minimal when compared to other HVAC Solutions. Furthermore, active chilled beam technology can provide the heating as an integral part of the water driven cooling and fresh (filtered) air ventilation system, all with the shallow depth construction of the previously mentioned Eco™ and Halo™ active chilled beams that are purposely designed for 'Healthcare' applications.

Cooling for Hospitals and other 'Healthcare' applications need to be designed as a bespoke cooling solution to fit around the facilities requirements, whilst prioritising the health and Wellbeing of patients and other building occupants.

Important aspects to consider include:

Reduced Risk of Contamination

Mechancial filtration at the Air Handling Unit can be effective in producing virtually bacteria-free supply (primary) fresh air in hospitals. It is best practise to extract air from the corrindors where old air is extracted.

Dependant upon the patient room and heat loads, one or more Healthcare active chilled beam unit (each compact in design and with no need for seperate grills which take up more valuable space) can supply fresh and re-circulated air within the room space which prevents the conditioned clean air coming into contact with the ceiling void air, or potentially contaminated air from other rooms.

This is also due to the Eco™ and Halo™ active chilled beam being designed with a closed back to prevent the potentially contaminated void air getting into the the beam and affecting the fresh and circulated air.

FTF Group's healthcare Active Chilled Beam units designed and manufactured to be extremely low maintenance due to the beams having no moving parts, with all filters and controls for the beams being located at the Air Handling Unit or within corridors. The healthcare Active Chilled Beams units are fully accessible from the room space below, allowing for inspection and cleaning of the coil and induction grille to be performed from the lower face of the Chilled Beam unit, without having to remove any ceiling tiles and/or accessing the ceiling void.

Thermal Comfort and Indoor Air Quality

The Active Chilled Beam system will typically control temperature and humidity in the occupied space via the air handling unit with a constant supply of primary air (minimum fresh-air ventilation requirements are met at all times) and chilled water (above dew point) for sensible loads.

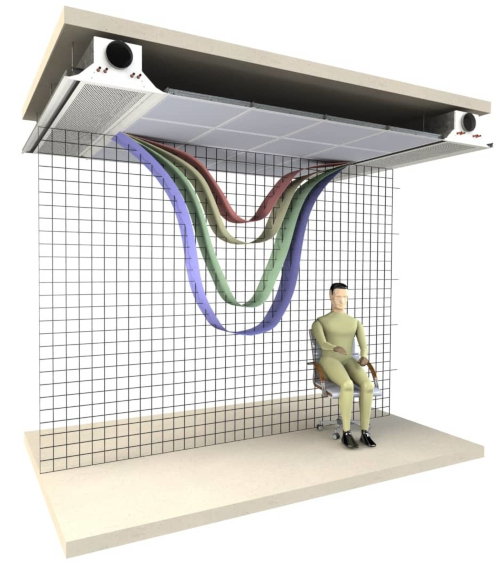

All of FTF Group's Active Chilled Beams allow for the air to be distributed evenly throughout a room (5:1 induction ratio) in a controlled manner with the use of the coanda effect. Unlike other Chilled Beams on the market, FTF Group's Active Chilled Beams feature a 'Turn Down' facility as standard, which allows the beams to create a full coanda effect even at lower air pressures, when air pressure is reduced to lower the supply air volume to suit reduced occupancy levels.

This is especially useful when room areas are not populated to full design occupancy and the air is reduced to supply accordingly. The use of the Coanda Effect, at both normal and low air pressures, is crucial to providing occupants with the highest Thermal Comfort, as without the Coanda Effect the air supplied will not entrain across the room and instead 'dump' into the occuipied space below, causing discomfort/draughts.

Energy Saving (Net-Zero / Carbon Reduction)

The ACB system operates on elevated chilled water supply temperatures (designed to run 'dry', above dew point from 14°C to 17°C supply temperature) and have no moving parts (e.g. no fans or motors) which provide a more energy efficient system when compared to a fan coil unit solution and is a good step in the right direction for Net-Zero.

These systems are typically operated below dew point (wet) on a 6°C or 7°C supply temperature (which also means a required added cost of a condensate drip tray) and are also supplied with individual fans and motors.

As mentioned before, there are no moving parts within ACBs and therefore the maintanance cost is significantly lower compared to fan coil units. With ACBs requiring the batteries being cleaned, using a vacuum cleaner and a pipe attachment, and the rest of the unit simply needing the surfaces cleaned with a damp cloth every 4-5 years in normal applications and cleaned to suit frequencies of internal hospital standards for healthcare applications.

Due to the moving parts within fan coil units, the maintenance costs are significantly higher. The filter will need changing, the condensation system will need cleaning over 3 times per year, with the motor and fan coil parts needing replacing every year. On a yearly basis this does not seem a significant cost, however, over the course of the 20-year life cycle of the unit this adds up and is a cost that can be eliminated with the use of Active Chilled Beam solutions.

Quiet Operation

High ambient noise levels in patient rooms is believed to have negative impacts upon patients and their health and Wellbeing. These impacts can range from a lack of sleep, elevated blood pressure or extended recovery times.

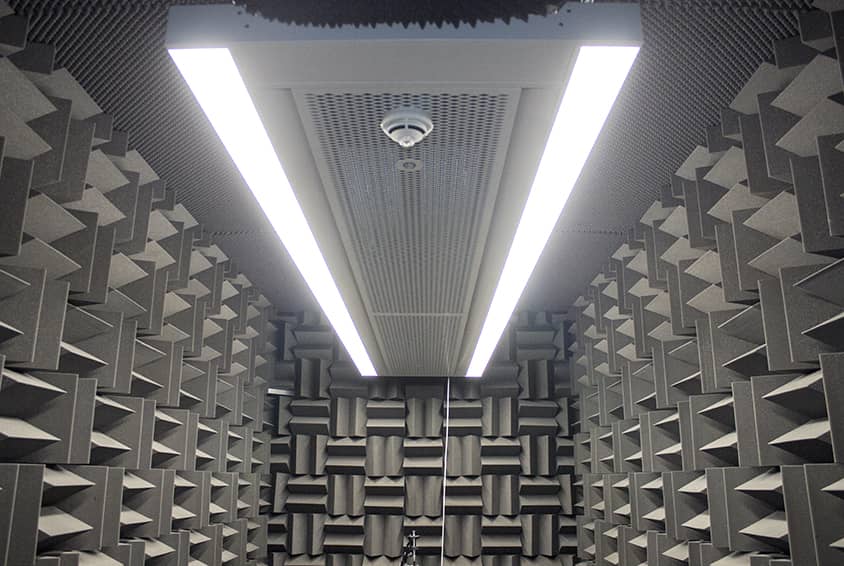

ACB units are designed to contribute virtually no detectable noise to occupied spaces, with sound pressure levels which can be below 25dB. Fan Coil units typically create more noise (higher sound pressure) levels, typically 38dB which can have a detrimental effect to patient recovery/occupancy room comfort.

FTF Group® has significantly invested into testing facilities for their products, at their UK head office and technical facility having in-house Climatic Testing Laboratories (x3), Lighting Laboratories (x2), and an Acoustic Laboratory (x1).

Minimal Maintenance

Due to Chilled Beams having no internal moving parts, they have little maintenance requirements. FTF Group's Healthcare Chilled Beams provide a drop down battery function due to the removable under plates allowing for the heat exchangers battery to be lowered. This enables full access to the recirculation air chamber, and also full cleaning of all four sides of the battery can take place.

With large amounts of bedding used in patient-care areas of hospitals, lint from the bedding can become airbourne. Although Chilled Beams do not usually attract large amounts of lint, as the velocity of the recirculated air moving through the dry coil heat exchanger battery element is quite low compared to other HVAC systems, it is still a good practise to perform routine inspection when cleaning the air casing.

Ordinarily the cleaning of the battery from lint is bi-annually, along with a wipe down of visual surfaces with a damp cloth with mild detergent and/or anti-bacterial cleanser.

Eco™ Active Chilled Beam

The Eco™ Active Chilled Beam contains a number of patented performance enhancing features, including the 'burst nozzle' arrangement which can also be found on FTF Group's other Active Chilled Beams. The use of the 'burst nozzle' arangement encourages induction, delivering equal distribution of air discharge with minimal noise.

The heat exchanger batteries are also fitted with extruded aluminium profiles to enhance performance as well as providing the continuous clip on facility for the underplates. As mentioned before, the healthcare version of this beam allows for the exchange battery to be lowered down to allow cleaning on all four sides of the heat exchanger.

The Eco™ beam, which can have integrated heating with two seperate connections (2x pipe connections for cooling and 2x pipes for heating), features the closed back design as mentioned before to provide better quality of recirculated air. This is because the recirculated air does not mix with the 'dirty' ceiling void air.

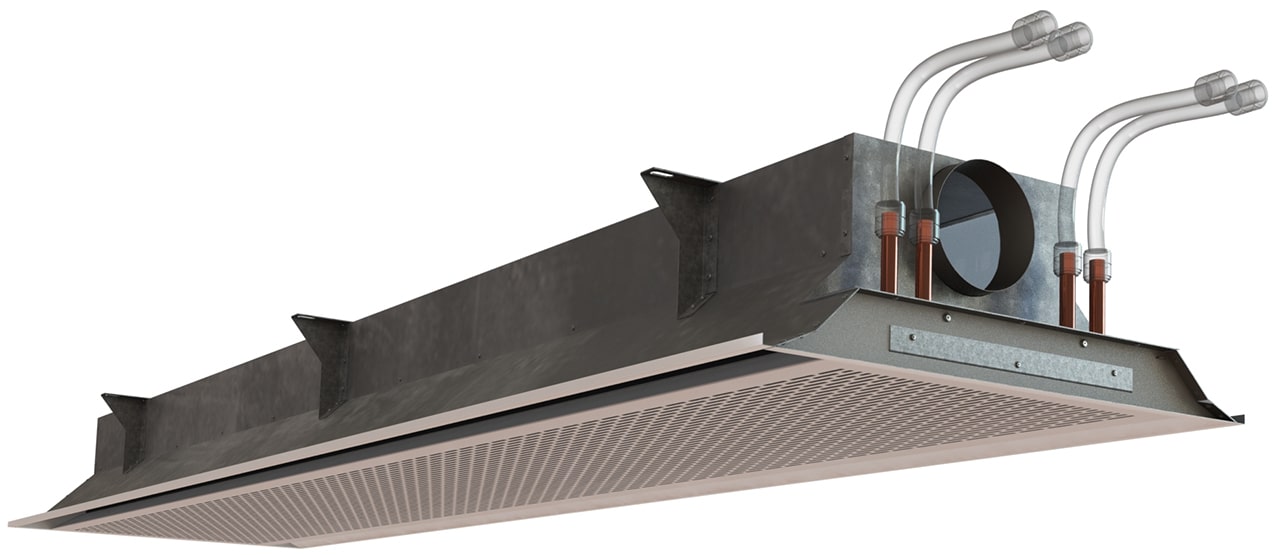

Halo Active Chilled Beam

The Halo high-capacity and small footprint Active Chilled Beam has become increasingly popular as they can free up valuable ceiling area whilst still handling the significant heat gains and losses.

The unique 360° discharge characteristic helps to deliver high levels of occupancy comfort, which as highlighted before is very key to patient health and wellbeing. This optimal method of distributing the discharged air in all directions means the shortest possible air throws are created